A number of drafted blog posts have fallen by the wayside around here, and I hope to return to them in the early new year, but I’ve found that it’s easiest and most satisfying to post about my active projects, so I’m leaping out of chronology to talk about what’s on my work table now: a Tamarack Jacket.

Tamarack Dreams

I’m a big fan of Grainline Studio, from the pattern designs to Jen’s blog styling. The contemporary aesthetic and thorough instructions have played a huge role in my re-discovery and enjoyment of sewing in the last few years. That said, when Jen started hinting on Instagram that a quilted jacket pattern was in the works, I thought it looked great but was not something I would make — it looked laborious and I wasn’t sure if it fit my style. Yet by the time Grainline Studio released the Tamarack Jacket, temps here in Minnesota had dropped to the mid-40s and I had realized that my outerwear options were severely limited.

On the spectrum of warmth, between my Uptown jacket and a very heavy wool coat (one of my favorite thrifting scores), I was left with a 3/4-sleeves jean jacket and a zip-up fleece jacket I’ve held onto since age 12 and usually reserve for sporty activities. Suddenly, a Tamarack Jacket seemed absolutely essential for my daily life and wardrobe. I bought the pattern immediately.

One of the outcomes of participating in Slow Fashion October has been a growing awareness that I have enough. In fact, I have plenty. I have an abundance of beautiful yarn, fabric, garments to upcycle, dye project materials, etc. Since time is my limiting factor, I’ve gathered a plentiful stash which I am excited to work with, but very wary of growing.

Turning to my stash, I quickly decided that two yards of this Organic, U.S.A. grown and made chambray would be perfect for my Tamarack. Purchased back in the summer with an Archer in mind, the chambray is colorgrown cotton, which is bred to produce natural pigments instead of plain white boules. The green color is very faint, with a silvery tone to it, and while it’s really lovely, it unfortunately looked terrible on my skin tone.

Indigo to the Rescue

Last year, my wonderfully thoughtful partner, Jenn, gifted me an indigo shibori kit from Botanical Colors. For nearly a year I have treasured this kit — so much so that no project seemed worthy of its use. With the end of fall fast approaching, I seized the opportunity to finally make the indigo vat, with visions of a rich blue Tamarack dancing in my head.

The kit includes everything needed to create an organic indigo vat, or fruit vat, as designed by French chemist Michel Garcia. I followed the instructions provided by the kit, and cross-referenced The Modern Natural Dyer and this guide from Maiwa.

Though I’ve dyed with indigo before, I had never created my own vat, and I have to say it’s truly a magical process. If you’re not familiar, natural indigo requires a reduction process to make the dye available to fibers, meaning you have to remove the oxygen from the vat. Though blue on the surface, a reduced indigo vat is yellow-green, and fabric pulled from the vat is green at first, then turns blue as it is exposed to oxygen. An organic vat can be made in several ways (see the Maiwa guide for more), but the fruit vat uses fructose to reduce the indigo, and slaked lime (calcium hydroxide) to raise the pH (i.e. make it basic).

I decided to dye on an unseasonably warm weekend, knowing it would be one my last chances to be outside in 60 degree weather for many months. I prepared the mother in a large glass jar (above photos), let it rest and reduce, then created the vat in a 5 gallon bucket. Outside, I set up a clothesline and brought out 2 extra buckets filled with some water for oxidizing and rinsing the fabric.

While planning out the project, I was concerned that the kit would not be strong enough to get at least a medium shade of blue on all the fabric for my Tamarack. My 2 yards of colorgrown cotton were not quite enough to supply all the lining and exterior pieces, so I decided to use the largest scraps of similar-weight cotton from my stash for the remaining lining pieces. I didn’t want the jacket to look too hodge-podge, but I figured the indigo would be the great equalizer. So, after printing and assembling the pattern, I cut 2 of each piece from the various fabrics (back, fronts, sleeves, pocket).

All sources I’ve read say that you’ll get the strongest blues at the beginning of using your vat, so I started dyeing with my Tamarack Jacket pieces first to ensure a relative even color. I submerged each piece in the indigo for 4 minutes, moving the fabric through the vat gently to get an even color without adding oxygen to the vat. I hung each piece on the clothesline to oxidize (see below), and continued for additional dips to build the color gradually. Ultimately, I did two dips for the lining pieces and three dips for the exterior of the jacket. Once I felt satisfied with the shade of the Tamarack pieces, I continued dyeing other scraps and yardage from my stash; at the top of the post you can see the “before and after” piles and colors of fabric. After several hours playing the my indigo vat, the sun had set and I could tell the vat needed to be recalibrated (it had lost the bloom and coppery sheen on top, was cool in temperature, and producing very light colors).

Here are some of my indigo dyeing takeaways:

- Indigo is very temperature sensitive, and I found that the indigo mother reduced very slowly until I put it in a hot water bath and closely monitored the temperature. Once the temperature was steadily kept between 110 and 120 degrees (F), the indigo sedimentation fell steadily to the bottom of the jar and the navy blue bloom with coppery scum grew at the mouth. This is what you need to look for to know that the mother is ready.

- You probably don’t need to use the whole kit in one go. The kit says it contains enough indigo to dye 6 T-shirts to a medium shade. It doesn’t provide the weight of 6 T-shirts but I figured between the Tamarack pieces and other items I wanted to dye in my stash, I would exhaust the whole kit. In hindsight, I would recommend starting with half the ingredients in the kit, that way you have some fructose and lime leftover to help recalibrate the vat, and some additional indigo to create a new mother and reinvigorate it.

- You can reuse an organic indigo vat! The instructions from Botanical Colors don’t seem to mention this, but both the Modern Natural Dyer and Maiwa suggest that the vat can be saved and brought back to life. After drying all of my dyed pieces, I realized that the front pieces of the Tamarack pattern had a streaky effect where the dye washed out unevenly. I was disappointed, but then realized I could bring the vat back to strength and overdye them to hide the mistake. I followed the helpful guidance from Catherine Ellis’ blog and simply added fructose and made sure that my vat stayed between 110 and 120 (on the stovetop). It smelled like maple syrup and though the vat didn’t last as long, I concealed the streaks with 2 more dips per piece of the jacket.

I’m quite excited to begin quilting my Tamarack Jacket, though I’m nervous because I’ve never really quilted anything. I’m also a little nervous that repeated dyeing and washing may have shrunk my pieces or caused too much fraying in the seam allowance. What if I make the whole jacket up and it’s too small? It may have been wiser to dye the fabric instead of the pre-cut pieces. But I’m forging ahead with test quilting and basting my “quilt sandwich.” On my next post, I’ll write about my thought process and research into sourcing quilt batting.

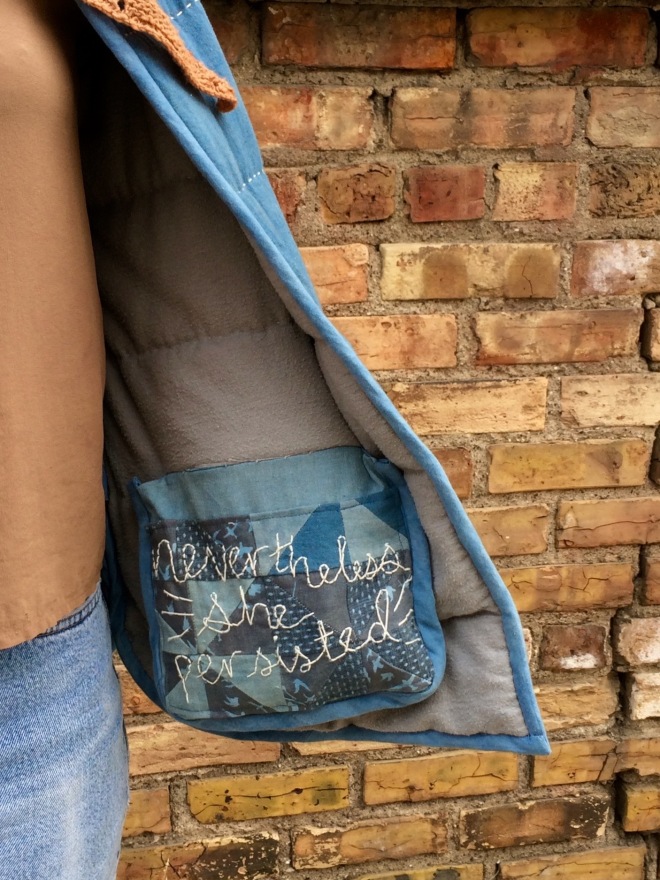

Do you ever just get in the creative flow when you stop questioning yourself and start letting your hands carry out your mind & heart’s vision? I tend to overthink things, to work very slowly, but in this case I was both running out of time and running on excitement for getting to touch and admire some of my favorite fabrics again. The large panel on the front and back is linen that I bunched up and dyed in indigo, the gingham is from my

Do you ever just get in the creative flow when you stop questioning yourself and start letting your hands carry out your mind & heart’s vision? I tend to overthink things, to work very slowly, but in this case I was both running out of time and running on excitement for getting to touch and admire some of my favorite fabrics again. The large panel on the front and back is linen that I bunched up and dyed in indigo, the gingham is from my